MASKING TAPES, FOIL

MASKING TAPES, FOIL

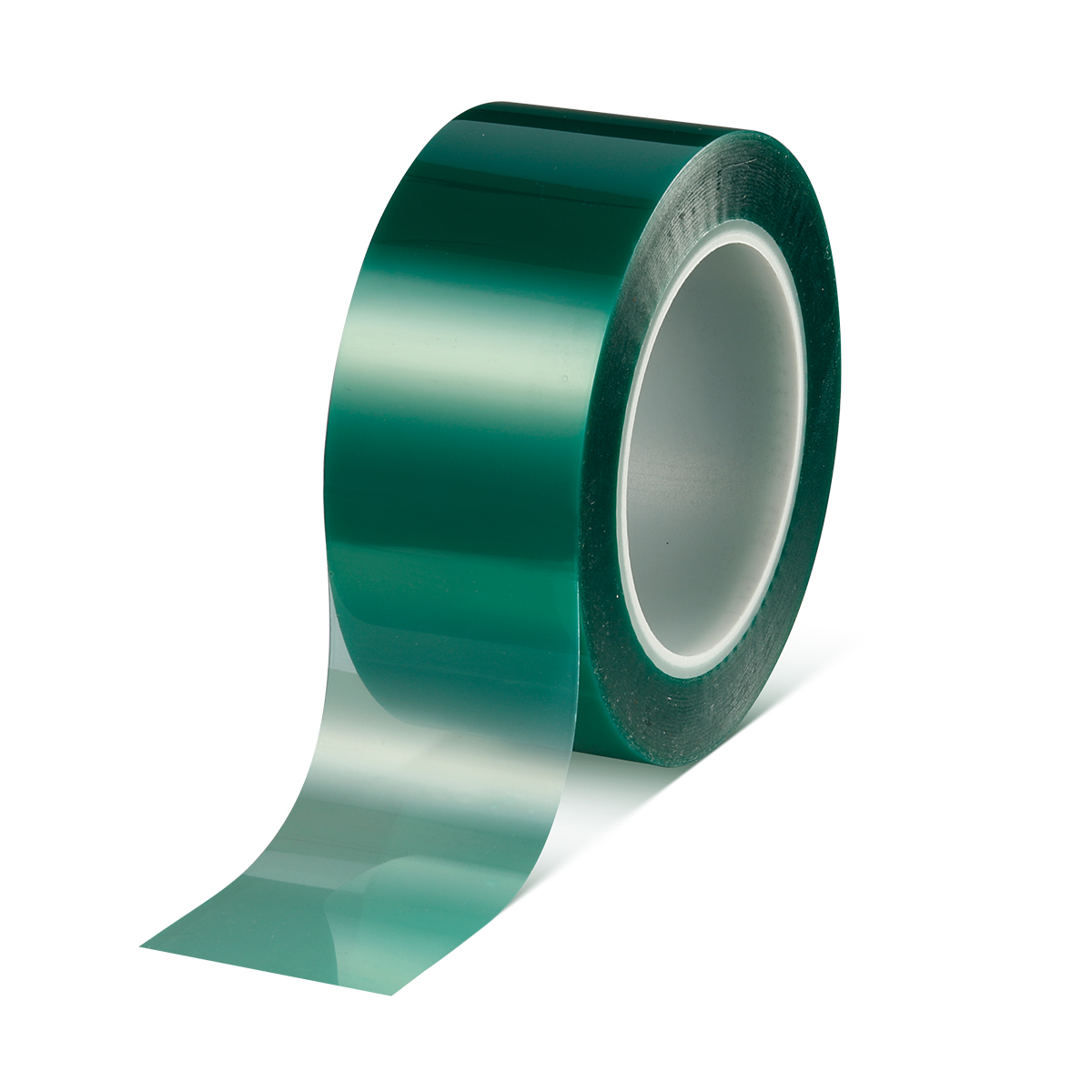

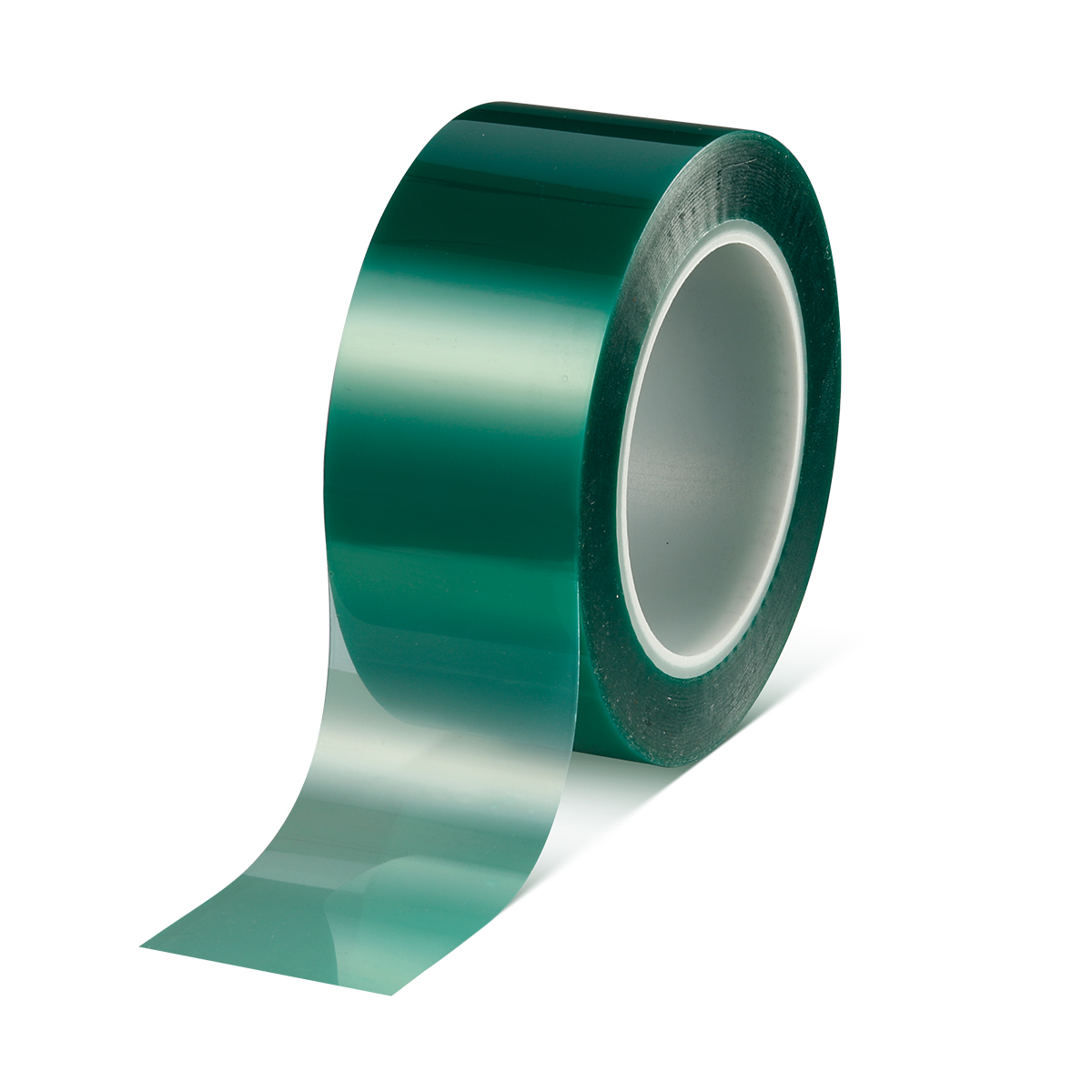

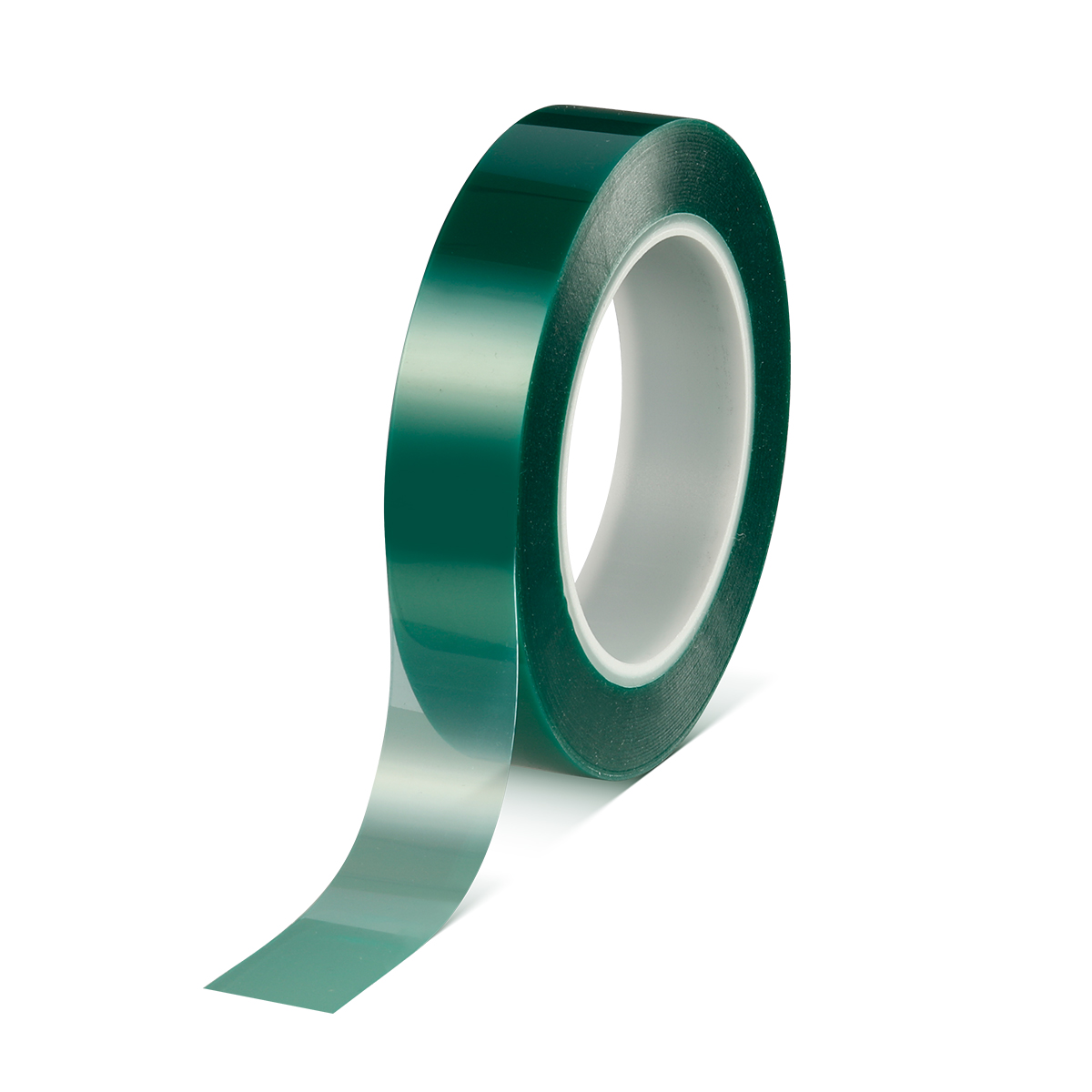

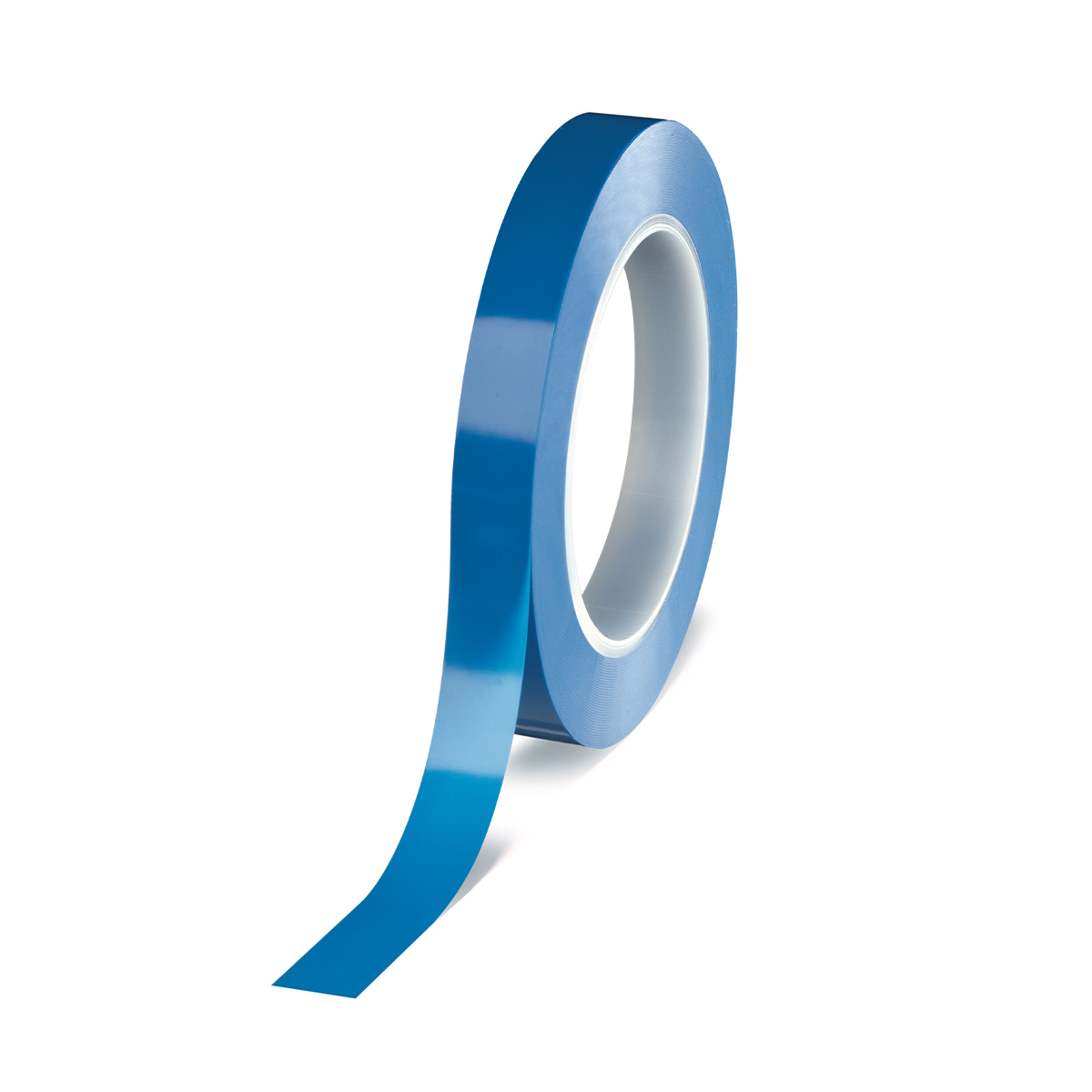

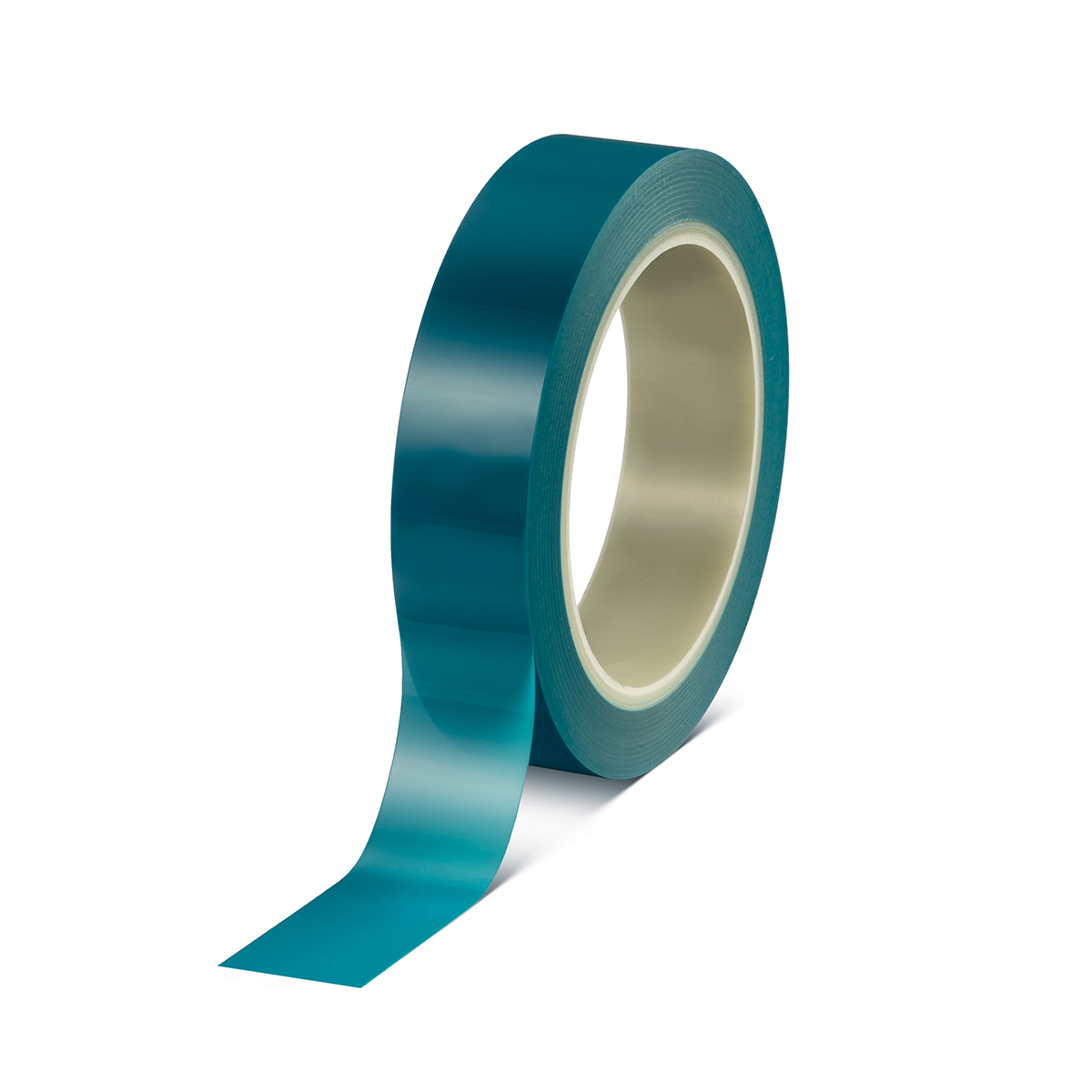

tesa® 50600

PET Masking Tape 220°C with Silicone Adhesive

Product description:

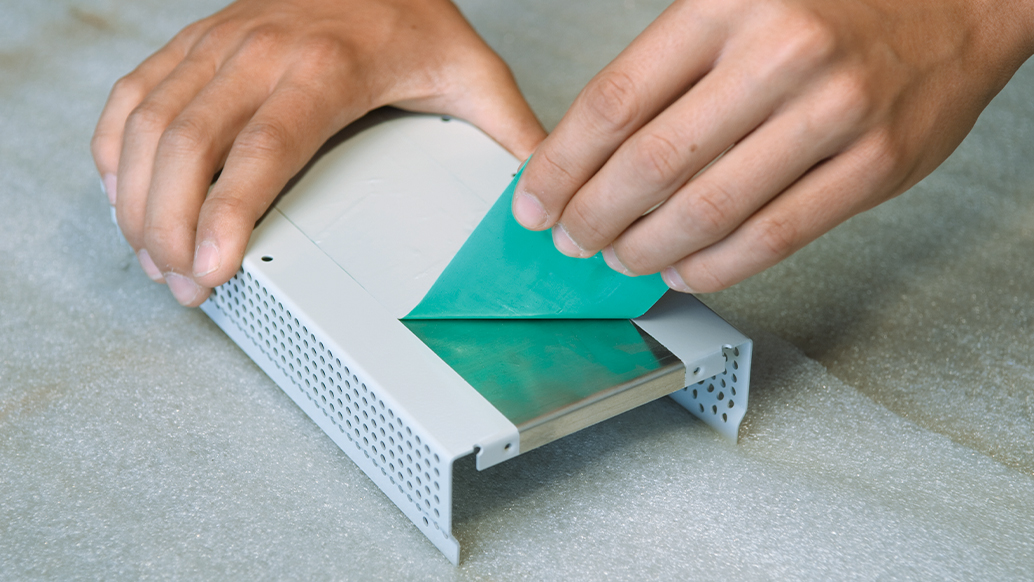

tesa® 50600 is a green-translucent, high-temperature masking tape featuring a polyester backing with a silicone adhesive. tesa® 50600 is used for various applications, especially for masking during powder-coating processes, surface protection applications or bonding and splicing of non-polar materials. tesa® 50600 masking tape is also available in a version with a liner.

Product Features:

Application Fields:

Product Construction:

Backing material PETP

Total thickness 80 µm

Type of adhesive silicone

Adhesion to Values:

Adhesion to Steel 4 N/cm

Properties:

Temperature resistance 220 °C

Elongation at break 110 %

Tensile strength 75 N/cm

Hand tearability low

Easy to remove Yes

Photos:

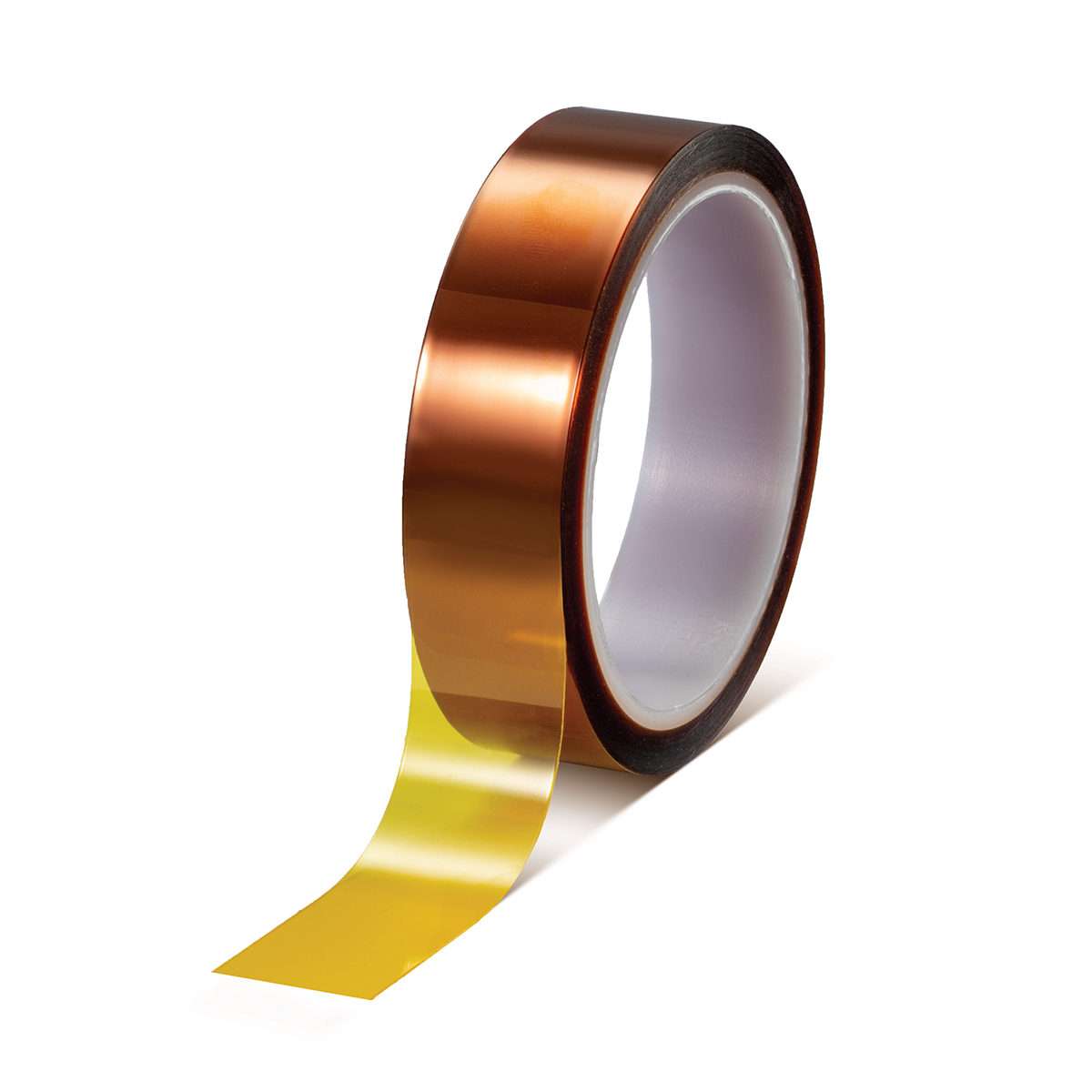

Products in the same category:

EKO-TECH® is a professional converter of tesa® brand materials. We manufacture and convert almost all available products from the tesa® tape range.

The most popular solutions are:

Longitudinal cutting of rolls to the required width.

Rewind rolls to individual lengths

Spooling material into cross-wound rolls

Die & Kiss Cut

Laser Cutting

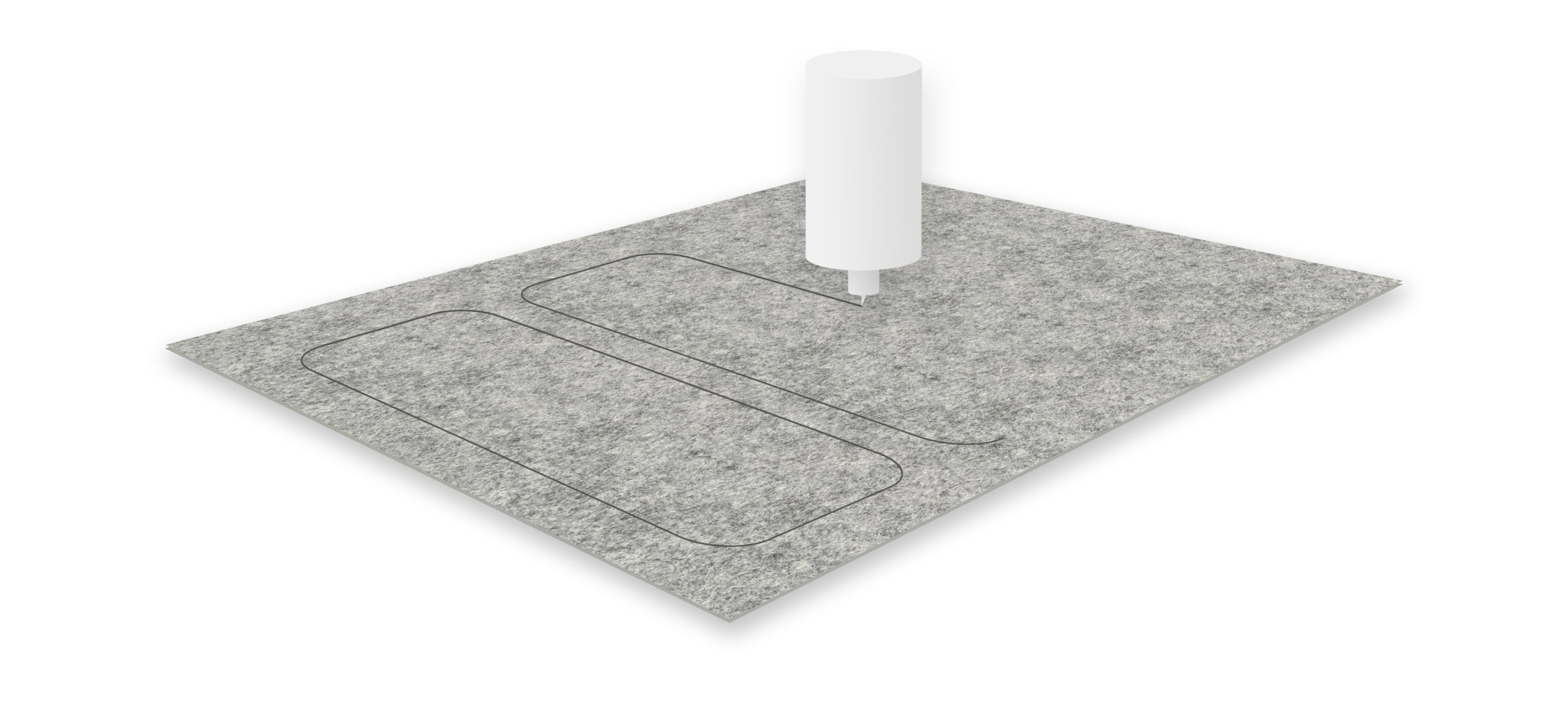

CNC large format cutting

CNC large format milling

Lamination to combine different materials and create sandwich composites

We specialize in customizing products – providing what the customer needs.

tesa® 4174

tesa® 4174  tesa® 4185

tesa® 4185  tesa® 4244 PV0

tesa® 4244 PV0  tesa® 4244 PV2

tesa® 4244 PV2  tesa® 4331

tesa® 4331  tesa® 4831

tesa® 4831  tesa® 50777

tesa® 50777  tesa® 51108

tesa® 51108  tesa® 51407

tesa® 51407  tesa® 51408

tesa® 51408  tesa® 54889

tesa® 54889  tesa® 60404

tesa® 60404  tesa® 61124

tesa® 61124  tesa® 61126

tesa® 61126  tesa® 7140 PV0

tesa® 7140 PV0  tesa® 7140 PV3

tesa® 7140 PV3