Double-sided transfer tapes

Double-sided transfer tapes

tesa® 75505

tesa® 4965 Transfer is a conformable, tackified acrylic transfer tape with a thickness of 50 μm. It is equipped with our proven and well-known tesa® 4965 adhesive, which is transparent, ageing resistant and has a high initial tack. tesa® 4965 Transfer therefore offers very good immediate grab to uneven surfaces and is suitable for a wide range of applications, such as lamination of lightweight, thin materials. Several products are equipped with this unique and high performing tesa® 4965 adhesive, and together these products make up Team 4965. This double-sided film tape assortment helps to easily select the most efficient tape based on customer demands, products, and processes. tesa® 4965 Transfer 50 μm can be ordered using order number tesa® 75505. Explore the benefits of the full tesa® 4965 assortment here: https://www.tesa.com/en/industry/general-applications/mounting/team-4965-assortment.

Product Features

Application Fields

tesa® 4965 Transfer is suitable for mounting and lamination applications of flexible materials and lightweight parts.

Example applications are:

Product construction

Backing material: none

Colour: transparent

Colour of liner: brown/blue logo

Thickness of liner: 70 µm

Total thickness 50 µm

Type of adhesive tackified acrylic

Type of liner glassine

Weight of liner 80 g/m²

Adhesion to Steel (after 3 days) 8 N/cm

Ageing resistance (UV) very good

Humidity resistance very good

Tack good

Temperature resistance long term duration 100 °C

Temperature resistance min. -40 °C

Temperature resistance short term duration 200 °C

Additional Info

Liner variants:PV12: transparent PET liner (75 µm; 105 g/m²)PV20: branded brown paper liner (70 μm; 80 g/m²)

EKO-TECH® is a professional converter of tesa® brand materials. We manufacture and convert almost all available products from the tesa® tape range.

The most popular solutions are:

Longitudinal cutting of rolls to the required width.

Rewind rolls to individual lengths

Spooling material into cross-wound rolls

Die & Kiss Cut

Laser Cutting

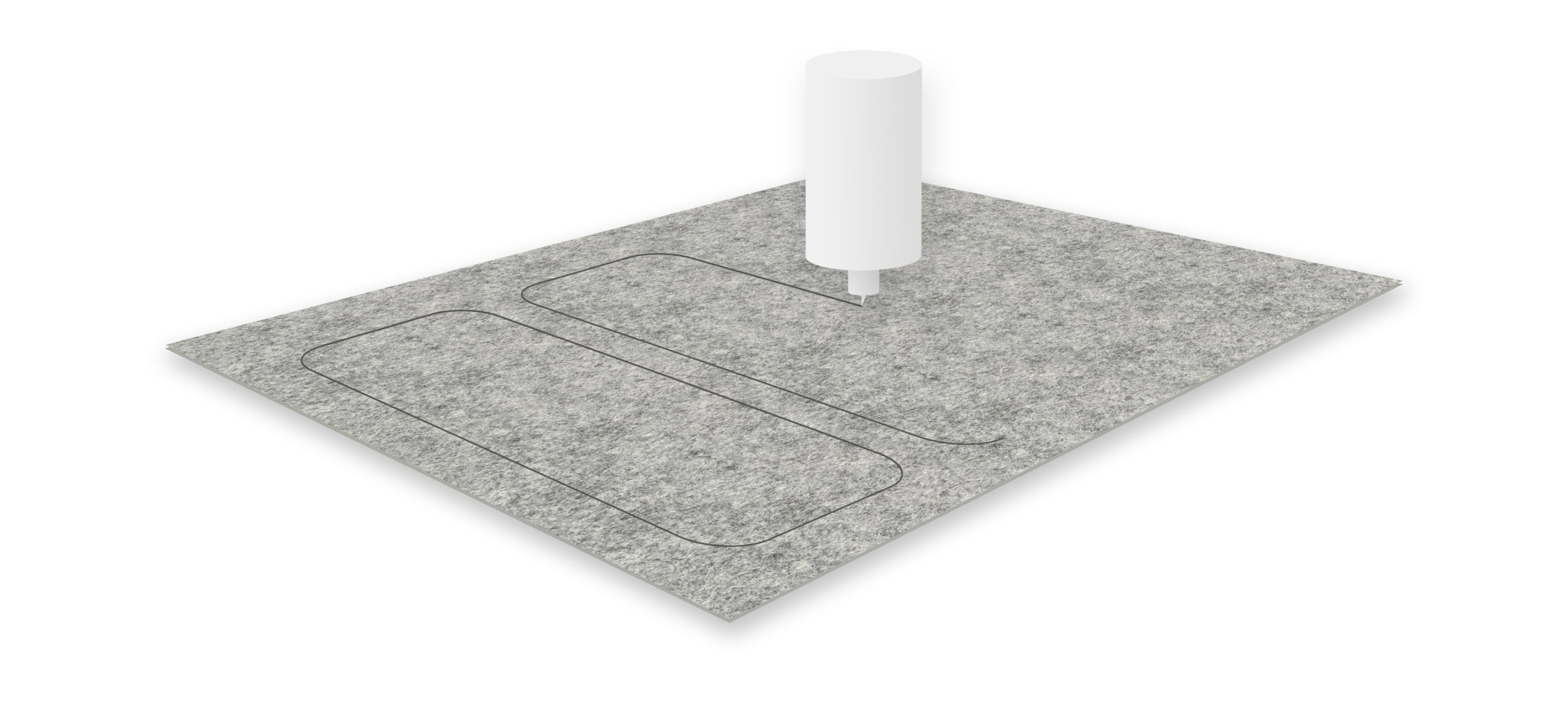

CNC large format cutting

CNC large format milling

Lamination to combine different materials and create sandwich composites

We specialize in customizing products – providing what the customer needs.

TESA Tapes