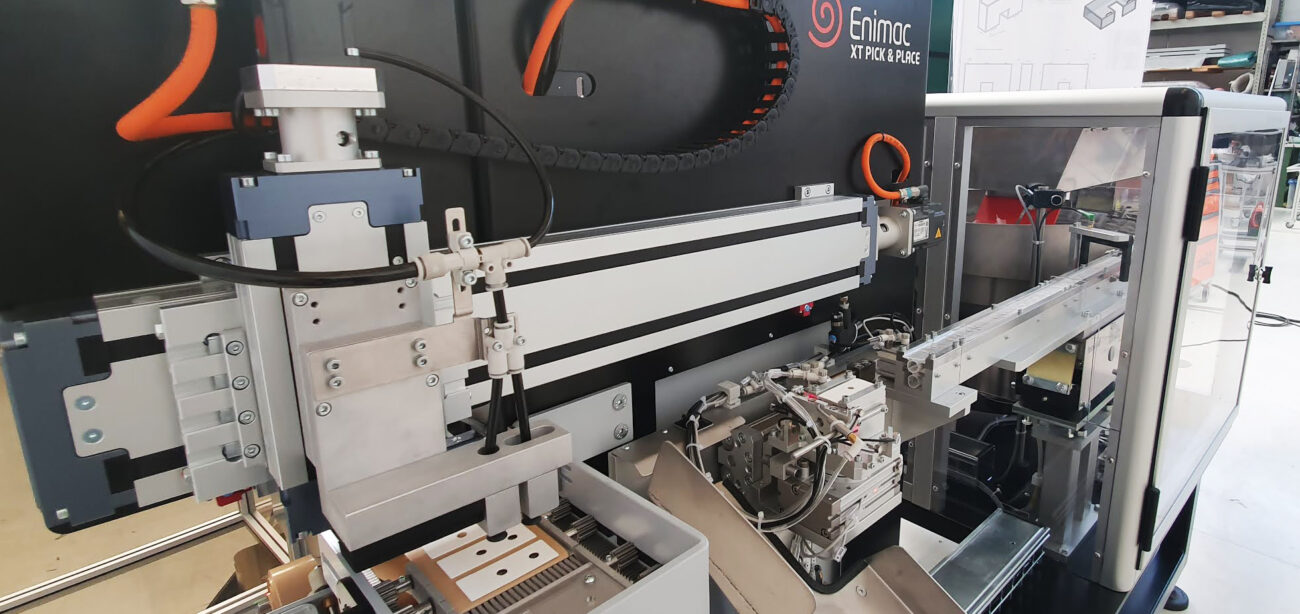

XT Pick & Place

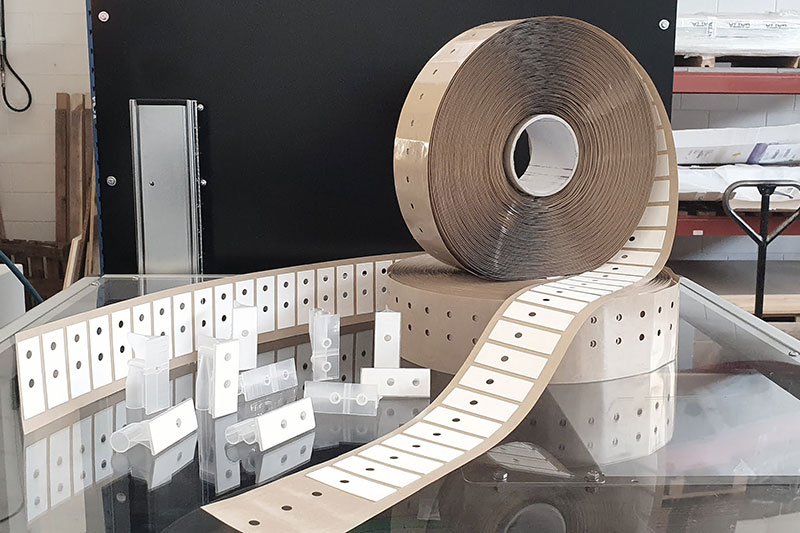

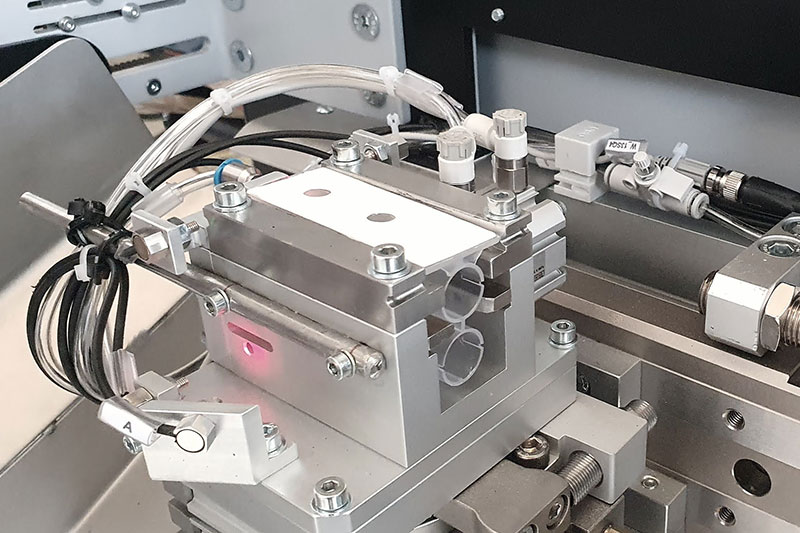

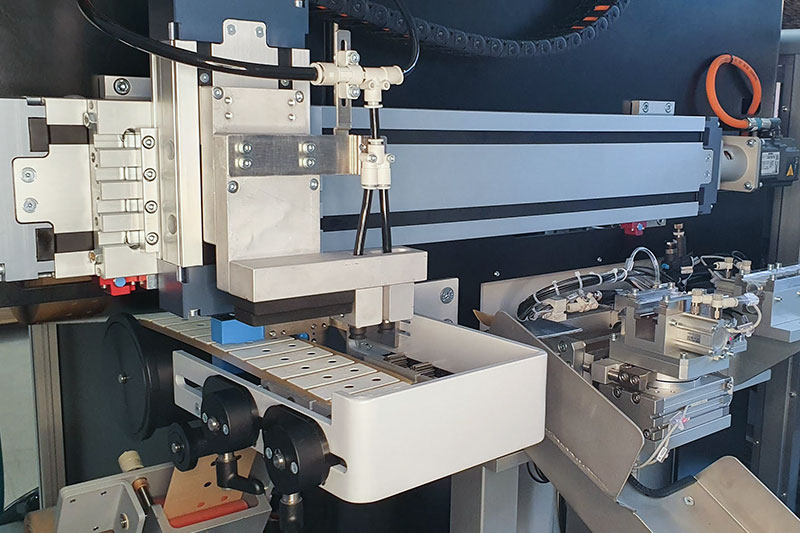

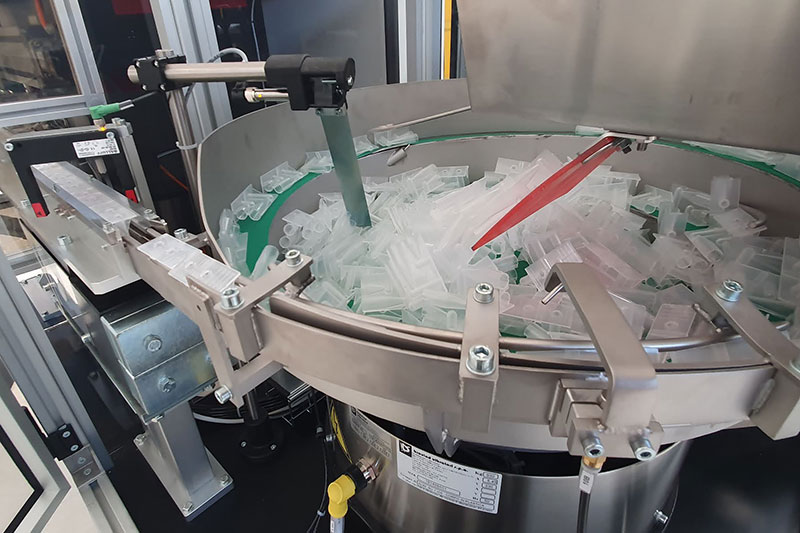

For the application of adhesive die-cuts on an article with a maximum production of about 1000 pcs/h. The die-cut tape is applied on a roll for easy application. The Pick & Place applicator picks up the die-cut onto the tape and applies it precisely to the article. Enimac manufactures Pick & Place solutions to apply die-cuts to objects. The example shows the application of a die-cut onto a medical item.

TYPE OF APPLICATOR

XT-PRO e-commerce can be mounted with different head types ranging from 25mm to a maximum of 100mm, offering for some of these the option of using from 1 to 3 different tape types on a single head to meet even the most complex application needs.

APPLICATION TEMPLATES

Our standard machines already offer a wide range of applications for flat and thin formats commonly used in the paper industry: posters, envelopes, pocket folders, packaging, etc., but also in any sector requiring single or double-sided adhesive tape to different flat surfaces up to a maximum thickness of 10mm or 15mm.

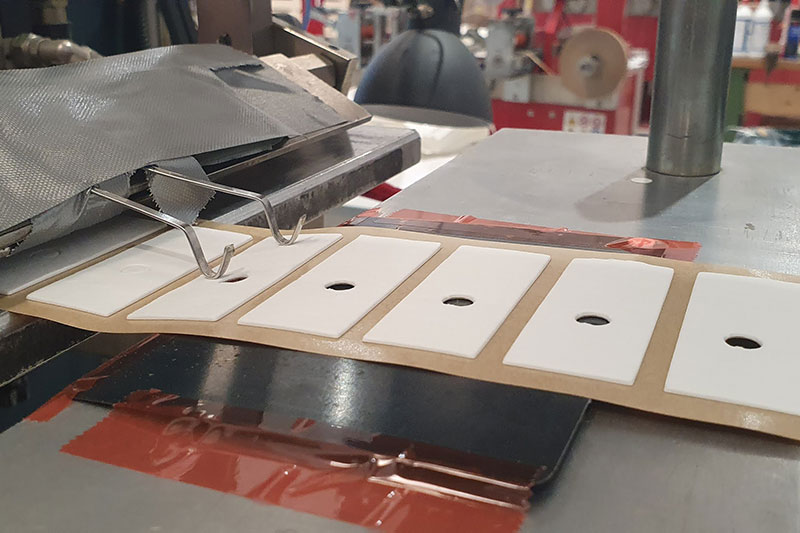

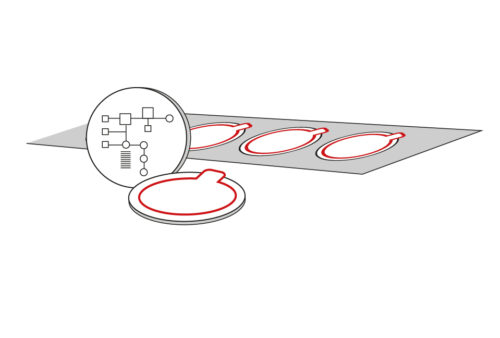

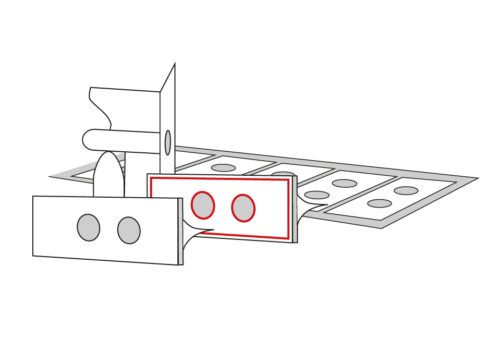

Example of applying double-sided adhesive tape to die-cut articles

Example of applying double-sided adhesive tape to die-cut articles